Aluminium Tube Specification

Aluminum tube are cylindrical pieces of aluminum that are hollow in the middle. They are often used in a variety of applications, including construction, automotive, and aerospace industries. Some common characteristics of aluminum tubes include:

- Lightweight: Aluminum is a lightweight metal, which makes aluminum tubes easy to handle and transport.

- Corrosion resistant: Aluminum is resistant to corrosion, which makes aluminum tubes a good choice for outdoor or harsh environments.

- Good conductivity: Aluminum is a good conductor of electricity, which makes it a popular choice for electrical wiring and other electrical applications.

- Ductile: Aluminum is a ductile metal, which means it can be easily shaped and formed into different shapes and sizes. This makes it a good choice for applications where the tube needs to be bent or shaped.

Aluminum tubes are available in a range of sizes and shapes, and they can be customized to meet specific requirements. They can be purchased from metal suppliers or online retailers.

Types of Aluminium Tube

There are several types of aluminum tubes, including:

- Seamless aluminum tubes: These tubes are made from a single piece of aluminum and do not have any seams or welds. They are strong and have a high level of precision, making them suitable for high-pressure applications.

- Welded aluminum tubes: These tubes are made by welding together two or more pieces of aluminum. They are typically less expensive than seamless tubes and are suitable for a wide range of applications.

- Drawn aluminum tubes: These tubes are made by drawing a piece of aluminum through a die, which gives them a smooth, uniform surface. They are typically used in applications where the surface finish is important, such as in the automotive and aerospace industries.

- Extruded aluminum tubes: These tubes are made by pushing aluminum through a die, which gives them a uniform cross-section. They are available in a wide range of shapes and sizes and are often used in construction and manufacturing applications.

- Rolled aluminum tubes: These tubes are made by rolling aluminum into a cylindrical shape. They are often used in applications where the tube needs to be bent or shaped into a specific shape.

- Anodized aluminum tubes: These tubes are treated with anodizing, a process that creates a protective layer on the surface of the aluminum. Anodized aluminum tubes are resistant to corrosion and wear and are often used in outdoor or harsh environments.

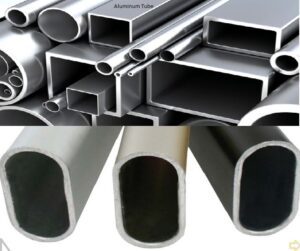

Shape of aluminium tube

Aluminum tubes can come in a variety of shapes, including round, square, rectangular, and hexagonal. The shape of the aluminum tube is typically determined by the intended application and the specific requirements of the project. Some common shapes of aluminum tubes include:

- Round aluminum tubes: These tubes are circular in cross-section and are the most common type of aluminum tube. They are used in a wide range of applications, including construction, automotive, and aerospace industries.

- Square aluminum tubes: These tubes have a square cross-section and are often used in structural applications, such as framing and support.

- Rectangular aluminum tubes: These tubes have a rectangular cross-section and are often used in applications where the tube needs to fit into a tight space or where a specific shape is required.

- Hexagonal aluminum tubes: These tubes have a hexagonal cross-section and are often used in applications where a strong, stable structure is needed. They are also commonly used in the aerospace industry.

Aluminum tubes can also be customized to meet specific requirements, such as having a specific shape or size. They can be purchased from metal suppliers or online retailers.

Aluminium Tube weight calculation formula

To calculate the weight of an aluminum tube, you can use the following formula:

Weight (kg) = (π x diameter^2 x length x density of aluminum)/4

Where:

- π (pi) is a mathematical constant, approximately equal to 3.14159

- Diameter is the distance across the center of the tube, measured in millimeters

- Length is the distance from one end of the tube to the other, measured in millimeters

- Density of aluminum is the weight of a certain volume of aluminum, measured in kilograms per cubic meter. The density of aluminum is approximately 2700 kg/m^3

For example, if you have an aluminum tube with a diameter of 20 mm, a length of 1 meter, and a density of 2700 kg/m^3, the weight of the tube would be:

Weight (kg) = (3.14159 x 20^2 x 1000 x 2700)/4

Weight (kg) = (3.14159 x 400 x 2700)/4

Weight (kg) = 3.14159 x 1080

Weight (kg) = 3382.9 g

Note: The weight of the aluminum tube will also depend on other factors, such as the thickness of the walls and the type of alloy used.

Aluminum tube suppliers in usa

There are many aluminum tube suppliers in the United States that offer a wide range of products for various applications. Here are a few options:

- Ryerson: Ryerson is a metal processing and distribution company that supplies aluminum tubes and other aluminum products. They have locations throughout the United States and offer a variety of shapes and sizes.

- Alcoa: Alcoa is a global aluminum company that supplies a range of aluminum products, including tubes. They have locations in several states in the United States and offer a wide range of sizes and shapes.

- TW Metals: TW Metals is a global supplier of aluminum tubes and other aluminum products. They have locations in several states in the United States and offer a variety of sizes and shapes.

- Reliance Steel & Aluminum Co.: Reliance Steel & Aluminum Co. is a metal distributor that supplies aluminum tubes and other aluminum products. They have locations throughout the United States and offer a wide range of sizes and shapes.

- Continental Steel & Tube Co.: Continental Steel & Tube Co. is a global supplier of aluminum tubes and other aluminum products. They have locations in several states in the United States and offer a variety of sizes and shapes.

There are many other aluminum tube suppliers in the United States as well. It is always a good idea to shop around and compare prices and options to find the best supplier for your needs.

Aluminum Tube Price today : US$ 1500-3000

Aluminum box tube size and thickness

An aluminum box tube is a type of aluminum tube that has a rectangular or square cross-section. The size and thickness of an aluminum box tube are important factors to consider, as they affect the strength and stability of the tube. Here is a list of some common sizes and thicknesses for aluminum box tubes:

- Width (mm): 20, 25, 30, 40, 50, 60, 70, 80, 90, 100

- Height (mm): 20, 25, 30, 40, 50, 60, 70, 80, 90, 100

- Wall Thickness (mm): 1, 1.5, 2, 2.5, 3, 4, 5, 6, 8, 10

- Length (mm): 1000, 2000, 3000, 4000, 5000, 6000

or

- Width (mm): 10 – 300

- Height (mm): 10 – 300

- Wall Thickness (mm): 1 – 10

- Length (mm): 1000 – 6000

Note: This is just a general list of sizes and thicknesses, and the specific sizes and thicknesses that are available may vary depending on the supplier and the specific product. It is always a good idea to check with the supplier for the exact sizes and thicknesses that are available. Your can read my previous post How To Calculate Weight Of Aluminium Chequer Plate?

Comments are closed.