Comparing GI and MS Pipe-Sheet-Grating

Comparing GI and MS Pipe , Sheet, Grating

Galvanized Iron (GI) and Mild Steel (MS) are two popular types of steel used in a range of applications, including construction, machinery, and infrastructure. In this article, we will compare GI and MS pipes, sheets, and gratings to help you understand the key differences between these two materials and make an informed decision when choosing between them.

Pipes

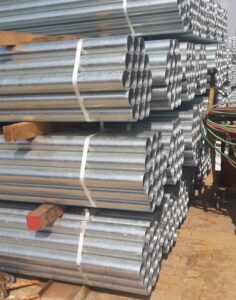

GI pipes are made of iron or steel that has been coated with a layer of zinc. The process of galvanization is done to protect the metal from rust and corrosion, making GI pipes an ideal choice for water supply and other applications where the pipes are exposed to moisture. These pipes are also available in different thicknesses and sizes, making them suitable for a wide range of applications.

On the other hand, MS pipes are made of low carbon steel that does not contain any alloying elements. They are cheaper than GI pipes and are often used for a variety of purposes, including gas and oil transportation, structural applications, and mechanical tubing. MS pipes are available in both seamless and welded forms, and can be further coated with other materials to enhance their properties.

Sheets

GI sheets are widely used for roofing and wall cladding in construction, thanks to their ability to resist rust and corrosion. They are available in various thicknesses and sizes, and are often pre-painted or coated with other materials to enhance their aesthetic appeal.

MS sheets, on the other hand, are made of low carbon steel and are widely used in a range of applications, including construction, shipbuilding, and machinery manufacturing. They are available in different thicknesses, sizes, and grades, making them suitable for a wide range of applications. Unlike GI sheets, MS sheets are not always coated or treated to resist rust and corrosion, so they may need to be treated further depending on their intended use.

Gratings

Both GI and MS gratings are commonly used for industrial flooring and as safety barriers in construction. They are made of metal bars that are spaced apart and welded together, and are available in different thicknesses, sizes, and patterns.

GI gratings are ideal for use in harsh, corrosive environments, as they are coated with zinc to prevent rust and corrosion. They are also available in different grades, making them suitable for a wide range of applications.

MS gratings are made of low carbon steel and are typically more affordable than GI gratings. They are suitable for use in environments that are not too harsh, but may need to be coated with other materials to enhance their properties.

In conclusion, the choice between GI and MS products depends on the specific requirements and budget for the project, as well as the intended use and environmental conditions of the finished product. GI products are more expensive, but offer better protection against rust and corrosion, making them ideal for harsh environments. MS products are cheaper and more suitable for general use in construction, but may need to be further treated to enhance their properties. It’s important to carefully consider your specific needs and requirements when choosing between these two materials

Comments are closed.